SAS Products Effectively Clean-Up OBM Filtercake

/One of our customers in West Africa put our Filtercake Removal & Breaker Products to the test, carrying out a laboratory evaluation to test their effectiveness on oil based mud (OBM) filtercake clean-up. Two products were chosen for this experiment, the SAS Breaker F and the SAS Breaker 162B. The aim was to simulate the effectiveness of each of these products on the dissolution and cleanup of filtercake formed by drilling fluid.

Test Parameters...

BHST - 200 F (93oC)

Pressure - 200 Psi

Brine - KCL weighted to 9.5 ppg

Duration - 24 hours shut in period

The results...

In the first test we used:

Breaker F: 7.5% by volume - 0.075bbl/bbl

Breaker 162B: 8% by volume - 0.08bbl/bbl

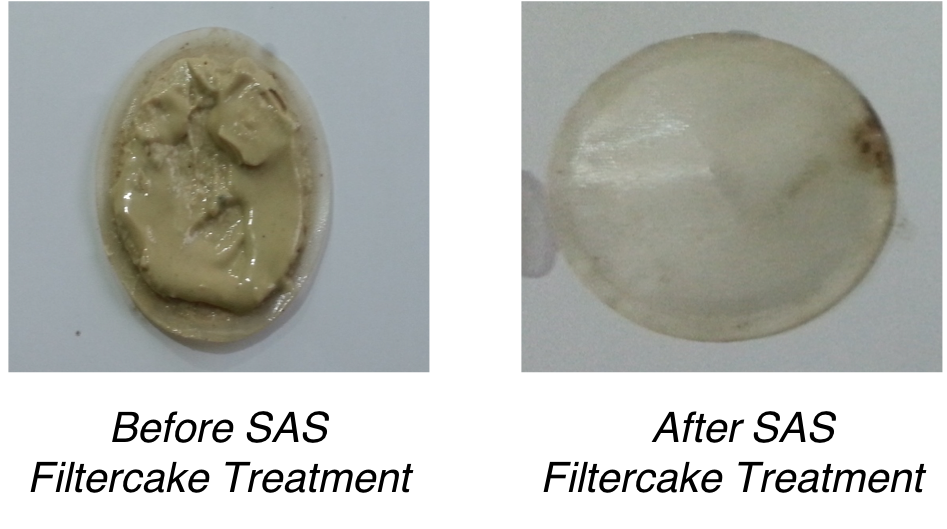

This combination completely dissolved the filter and there was no residual carbonate left on the filtercake after application (pictured below).

In the second test we used:

Breaker F: 10% by volume - 0.1bbl/bbl

Breaker 162B: 8% by volume - 0.08bbl/bbl

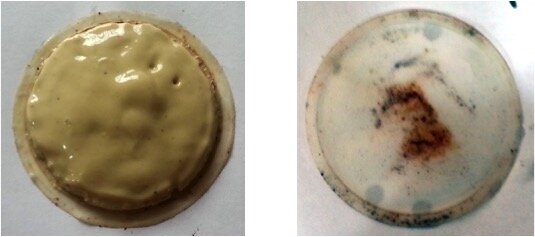

This approach was also successful in completely dissolving the filter, leaving no residual carbonate on the filtercake (pictured below).

We always provide our customers with successful results, and we can do this for you too. SAS keep costs down and get production up, so why not contact us today!