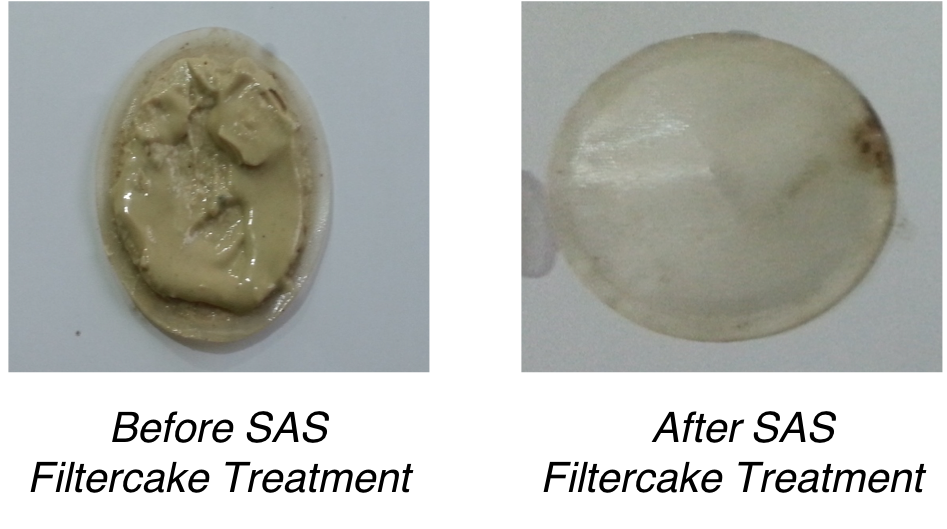

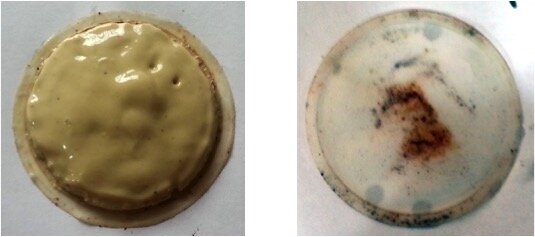

Remove Your Risk with SAS Breaker Products

/Calling all oil operators - why pay the price for inadequate product development? By using SAS Filtercake Breaker Products you could remove the uncertainty of using bespoke formulations that have proven in the past to be difficult and risky. Here's how...

We all know microemulsions can be fragile and fickle chemistries – especially where environmental variables such as pH, salt concentrations and temperature are concerned. Indeed, some of these environmental variables have been studied in great detail in order to maximize efficiencies of microemulsion products for use in the field - adjusting for salinity effects for EOR applications for example.

Since microemulsions are so specific in their requirements it has been hugely challenging for chemical providers and service companies alike to formulate products that perform beyond these boundaries and limitations – specifically where these variables have such a range from surface pumping to downhole well conditions.

From a pragmatic perspective huge risks, costs and logistical problems arise from having to overcome these issues. Simply blending a treatment pill sufficiently for downhole use, in itself, may be a huge obstacle if the formulation is not stable. It may take excessive work and time on the rig site to try and solubilize a chemistry in particular brines with significant equipment and manpower requirements.

Once solubilized some products have to be deployed into the well within a matter of hours in order to be effective and to avoid having these formulations fall apart and break down. If engineering malfunctions or other delays happen at this point, then the operator may end up paying the bill for hundreds of thousands of dollars in wasted chemical - paying a second time for a fresh batch to be made up after the obstacle to deployment has been overcome.

Then there is the risk of what happens downhole when the conditions (and especially the temperature) may change. Is it really worth taking that risk? We have an alternative!

SAS Production Services Breaker products are fully and readily soluble in brines meaning simple and straight forward preparations - needing less equipment and fewer personnel due to brine compatibility. Our Breakers are also stable over time so any on site delays do not mean wasted cash and chemical – no need for new batches to be made and for hundreds of thousands of dollars to be discharged.

Finally, SASPS Breakers are both robust and temperature stable so they perform every time downhole. What's not to like? Don't take the risk of using bespoke formulations. Use the best. Use SAS Breakers.