How to Return a Well to the Original Permeability and Increase Production

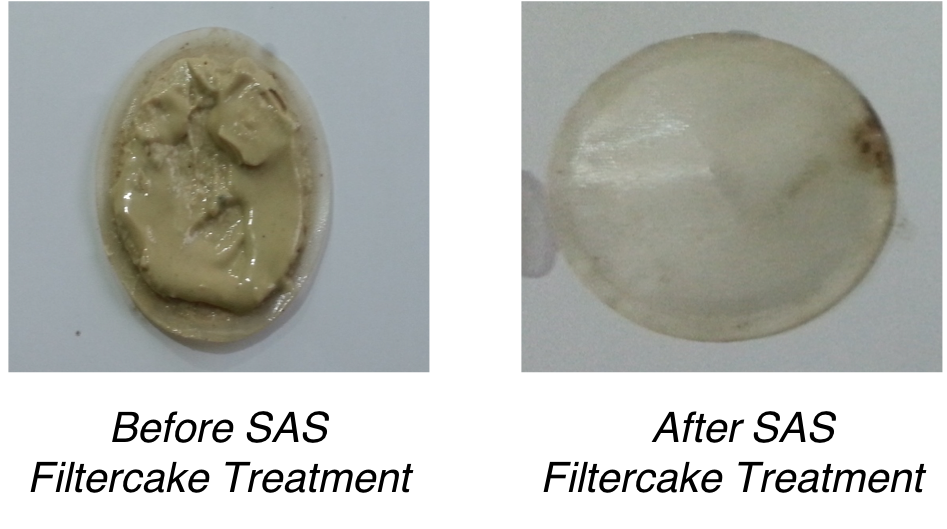

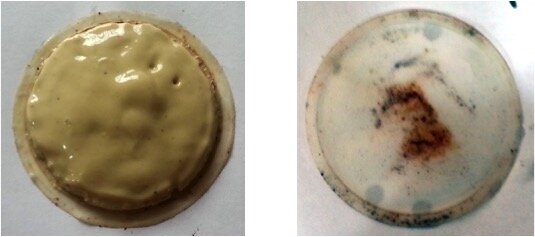

/There is less need to drill more wells when existing wells can be completely remediated. It is possible to realise a return to original permeability and experience up to 600% production improvement. SAS Filtercake Removal & Breaker products allow for either drilling fewer wells or the option to remediate existing wells to meet your field development plan and production target. You can double, triple or quadruple your return on investment through the application of our technology while halving the number of planned wells or workovers.

SAS Breaker products are superior in the following attributes:

Off the shelf suite of products can be quickly deployed no matter what your application is – no requirement for extensive lab customization, just some quick compatibility tests.

Single pill train with a one can application – minimize rig pumping time and equipment required, does not require viscous pills to remain intact while deploying.

Phase stable – when applied they will not separate and remain fully effective for extended periods of time.

Simple preparation and mixing, no shearing required – just add the solution to the brine of your requirements.

Can be designed to be instantaneous active or delayed action.

Can be utilized with Mono or Duo Valent Brines with zero detrimental effect.

Do not require temperature to activate and completely thermodynamically stable.

Extremely efficient diffusion where it water wets and coats all solids.

Breaks all in-situ emulsion blocks.

In-situ acid generators will solubilize all Calcium Carbonate base filtercakes.

Creates fluidity and full mobilization of filter cake solids and all fines.

Smaller delta-P in producers and injectors resulting in substantially reduced reservoir damage.

What is the value to you of a simply applied solution that effectively gives you ‘free wells’? Why not get in contact today and find out!

For more information about these impressive products download the Product Data Sheets here: